The Advantages of Rapid Prototype Plastic Parts for Metal Fabricators

Welcome to DeepMould, where Metal Fabricators can explore the innovation and efficiency of using rapid prototype plastic parts for their projects!

Introduction to Rapid Prototype Plastic Parts

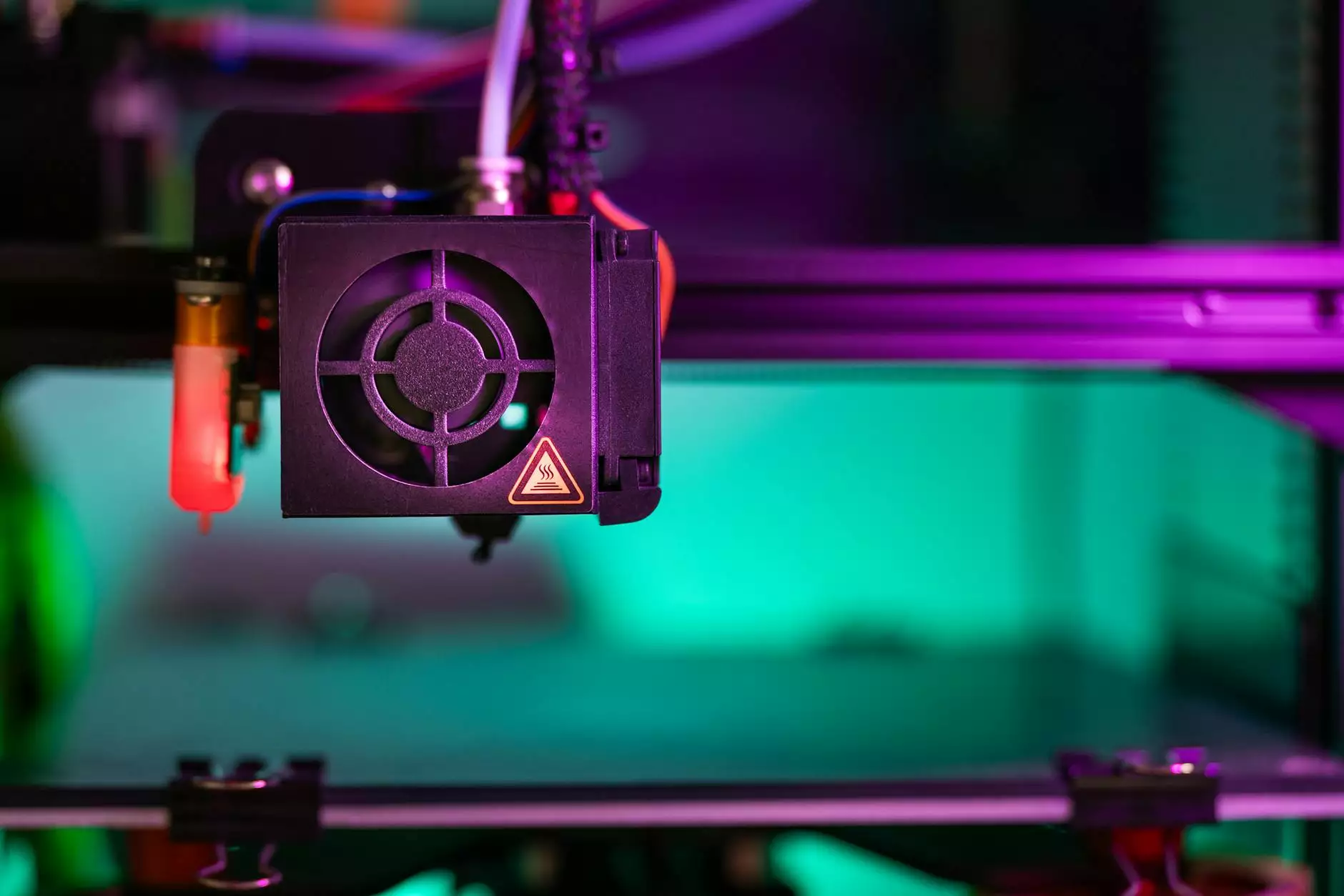

Rapid prototype plastic parts have revolutionized the manufacturing industry by offering Metal Fabricators a quicker and cost-effective way to create prototypes for their projects. These parts are created using advanced techniques like 3D printing, injection molding, and CNC machining. At DeepMould, we are committed to providing top-notch rapid prototype plastic parts that meet the highest standards of quality and precision.

Benefits of Rapid Prototype Plastic Parts for Metal Fabricators

1. Speed: One of the primary advantages of rapid prototype plastic parts is the speed at which they can be produced. Traditional manufacturing methods can be time-consuming, but with rapid prototyping, Metal Fabricators can have their parts ready in a fraction of the time.

2. Cost-Effectiveness: Rapid prototype plastic parts are often more cost-effective than traditional methods. By minimizing material wastage and reducing production time, Metal Fabricators can save on production costs without compromising on quality.

3. Flexibility: With rapid prototyping, Metal Fabricators have the flexibility to make quick design iterations and adjustments without the need for expensive tooling changes. This agility in the production process allows for more innovative and customized solutions.

Applications of Rapid Prototype Plastic Parts

Rapid prototype plastic parts find applications across various industries, including:

- Automotive

- Aerospace

- Electronics

- Consumer Goods

Why DeepMould for Rapid Prototype Plastic Parts?

DeepMould stands out as a premier provider of rapid prototype plastic parts for Metal Fabricators. Our expertise, cutting-edge technology, and commitment to customer satisfaction set us apart in the industry. When you choose DeepMould, you can expect:

- High-Quality Parts

- Fast Turnaround Times

- Responsive Customer Service

- Competitive Pricing

Conclusion

In conclusion, rapid prototype plastic parts offer Metal Fabricators a competitive edge in today's fast-paced manufacturing landscape. With DeepMould as your trusted partner, you can harness the power of rapid prototyping to bring your projects to life with precision and efficiency. Explore the endless possibilities of rapid prototype plastic parts at DeepMould today!